Optimizing Cannabis Products with Marvel

Optimizing Cannabis Products with Marvel

CASE STUDY

Overview

Optimizing cannabis production often comes down to grading and trimming. In this cannabis flower grading case study, a Southern California greenhouse set out to expand production by 50% while preserving its reputation for premium, hand-trimmed flower.

But as they looked toward this ambitious scale-up, they hit a wall.

The facility already operated on double shifts, year-round. More than 100 hand trimmers worked every day to keep up with the volume. While machine trimmers provided a rough first pass, the final product still relied heavily on manual finishing to achieve the clean, natural look trim quality customers expected. And as labor costs climbed, leadership faced a difficult question:

How could they decrease labor cost, preserve flower quality and scale up production at the same time?

What They Found

After analyzing the process, the team discovered that 70% of trimming labor was going into just 35% of the buds – the leafiest ones. They also found that flowers that only needed 1–3 manual snips could be processed much faster by hand trimmers and these flowers preserve their natural look and high quality look out of the machine trimming.

Solution

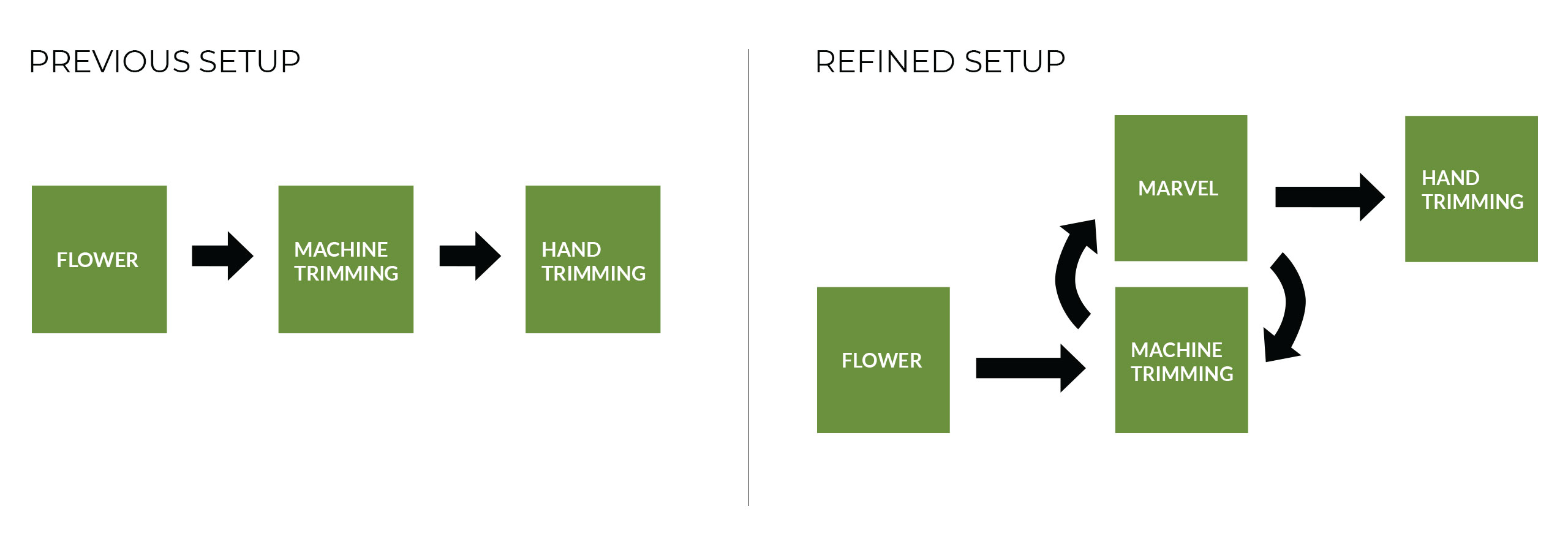

To address the variability in flower quality and the resulting bottlenecks at the hand‑trimming stage, the producer integrated Twister’s Marvel, an AI‑driven flower‑grading machine, into the processing line. Marvel employs near‑360° imaging and proprietary AI to analyze each bud’s morphology and visual complexity in milliseconds, then automatically sorts it accordingly in real time. They utilized the Intelligence of the machine to create consistency on flower batches going to the hand trimmer teams. The new upgraded process operates at

the most efficient operation point, flowers needing only 1-3 snips to get to hand trimmers.

This was achieved by intelligently determining the specific needs of machine trimming settings for various flower clusters in the batch using the Marvel AI system. Then, Operators apply these settings to the clustered batches, ensuring the buds exit the machine needing only 1-3 finishing snips. Hence controlling the whole process and consistently operating it at its optimum point.

The Outcome

The impact was immediate. Hand-trimming speed increased by 62%, jumping from 0.42 to 0.70 pounds per hour per person—with no disruption to daily operations. Manual trimming staffing requirements dropped as labor was reallocated more efficiently, and most importantly, the team hit its ambitious production targets. While saving $2 million a year, the return of investment was immediate.

As this cannabis flower grading case study, Marvel didn’t just add automation. It added clarity and data-driven insights. It gave the team a way to make smarter decisions with the same people, the same space, and the same values.

“Marvel helped us grow the right way, without giving up the hand-trimmed quality we’re known for.”