*Transcribed from video above

The Twister Grow Facility –

We don’t only make equipment, we are expert growers

Hey guys, Jay here with Twister. We’re in our grow room, this ones Mac 1. It’s looking really frosty and big. It’s starting to get heavy and is starting to fall. In the last two days, we’ve really lowered the temperature to help express the colors. You’ll see the purples are starting to come out of it. This harvest will be coming down in two days.

Is it important to remove fan leaves?

You’ll also notice we pull off all the big fan leaves in the grow, we did that in the last week or two. There are two reasons why you want to remove fan leaves:

- It helps the trimming process

- It allows the light to penetrate in the canopy. When the light gets in the canopy the smaller flowers and it gives them their color.

This is all going to get cut down and we’re going to hang dry it. Once it’s dry, we’re going to run this through tandem T4’s and triple T4’s.

How to scale up harvest processing?

So you bought a single T4 but you want to go faster or want to get even more productive? We’ll show you how you do that with tandem and triple T4’s. The machines will do 90-98% of the work depending on the strain.

The environment in the trim room makes a difference on results. Here are the specifications we have in place for a great trim process:

- Strain: Mac 1

- Dry Time: 10 day dry

- Flower Relative Humidity: 64%

- Room Relative Humidity: 50%

- Flower Quality: Stems don’t snap, but the leaves are crispy.

- Trim Room Temperature: 65° F / 18° C (but the colder the better)

Why is the trim room environment important?

Environment of a trim room is very important. We want the temperature below 65° F / 18° C. The colder the better, if the room gets hot the flower will get too sticky. As far as relative humidity in the space, you will want it at 50% ideally, but never above 55. If you go above 55, the flower starts pulling moisture from the air and it hampers your trimming process. Remember great flower in equals great flower out. Trimming equipment can’t take some larfy turds and turn it into gold.

We’ll get the remaining moisture out, down to 62%. So the stems will be snapping. We’ll do that using our curing process, which includes curing pucks. So when it comes out of to the cure containers, it will be big sticky blocks, like a wedding cake.

Does the Twister T4 work on all bud structures?

The Twister T4’s perform best when you have a really intricate large flower. Anything golf ball size, and smaller. If you’re running smalls, you’ll need close to zero touch up. What we have seen a lot of growers do is hand trim their tops and run the rest through the machines. Large top flowers are typically more intricate so you will do a bit of touch-up on that size. What if you have a really nodey strain? It sometimes has troubles getting into the nooks and crannies You may have to do some touch-ups but roughly only 2%.

Don’t growers hand trim for quality?

Some growers will claim hand trimming but to as a trick to speed up their process, they will put flower through the machine really fast and do a hand finish to give it a manicured look.

T4 Setup Used in the Video

The T4 Setup Specs

- 1st T4 Tumbler Speed: Level 4

- 2nd T4 Tumbler Speed: Level 6 (Full Speed)

- 1st T4 Blade Speed: Level 6 (Full Speed)

- 2nd T4 Blade Speed: Level 6 (Full Speed)

- Tumbler Style: F1 Tumbler

- Vacuum Bypass Used: No

- Leaf collection: Trim Saver

- Pitch Adjustment: Rails

- Input Conveyor speed: 20 to start, 10 when tumbler is full

- QC Conveyor Speed: 10

We have a tandem setup with speed control. I’m going to run the first T4 on level four tumbler speed. The second T4 tumbler will be on full speed. I’ll be running blades full speed on both machines to mill the trim small. The first machine is going to do the bulk of the work. The second machine will do the fine trim.

I’m running F1 tumblers for max performance. I am using trim savers to protect the trim and improve the air quality. We use a feed conveyor to keep the inflow consistent and throughput at a max it’s much better than a standard hopper. We also use a QC conveyor to visually inspect each flower so I can touch it up where needed. And I’m using the rail system to adjust the pitch of the machines, which influences how fast the flower moves through the machines.

Twister T4 Pre-Trim Checklist

Before starting your trimming process you will want to make sure that everything is in place to keep harvest moving smoothly.

- Do the conveyor belts move freely?

- Are the trim bins are empty?

- Are the trim filter bags clean?

- Are the blades are adjusted correctly?

- Is the pitch of the rail system adjusted?

How to adjust the Twister T4 blades

The fastest way to adjust blades is by sound. I turn the machine on and I turn the adjustment clickers until you hear blade contact. If there is no sound it means the blades aren’t touching. I adjust them so they make contact. I tighten one side first back it off, tighten the other side, back it off, then tighten them both at the same time for a consistent sound.

*Pro-tip – It’s important when you adjust the blades, to adjust them when the machine speed is at full speed.

How to adjusting the pitch of the T4 System

When you’re running Twister T4 tandem machines, you want a steeper incline that allows the flower to move through the machines fast. I like the flower to move through the machines within 45 seconds or less. We have a hand crank to adjust the angle. Start high and work your way down until you have the trim quality you’re looking for.

*Pro tip – Don’t use an impact driver on this, it’s too aggressive.

The Twister T4 Trimming Process

If you’re growing nice indoor flower, it’s very likely you’ve done a fan leaf pick. Ideally in the last two weeks of flower. This is important with this setup, if you don’t pick fan leaves, you should consider a much larger machine, like a Twister T2 or a Twister T-ZERO.

As I feed the machine, I want the tumblers to 30% full at all times to ensure the vacuum system can do its work.

I usually start at 20 on the feed conveyor this is to get flower into the machines quite quickly, and then I’ll slow it down to 10.

In the video you’ll notice running the process myself, I didn’t do any touch-up, I took everything off that needed a touch up and I put it. If you’re trimming flower by yourself, like I am, I send the flower through. I’ll watch the output and take flowers off that need to be touched up and I’ll put them aside. I’ll run them through on their own as a second batch. Those that need to be touched up again, I’ll do by hand that way you’re not mixing flower that’s been through the machine.

If I had someone on the QC conveyor doing quality control. We would have a 100% of the flower that entered that bin would be perfect.

Can you send flower through the T4 multiple times?

Could send flowers to the machine over and over? The most you ever want to send it through as two times. As I mentioned you only want the flower in the tumbler for a maximum of 45 seconds. If you don’t want to run the flower through a second time, simply have some people along the QC conveyor doing some small hand trim touch up.

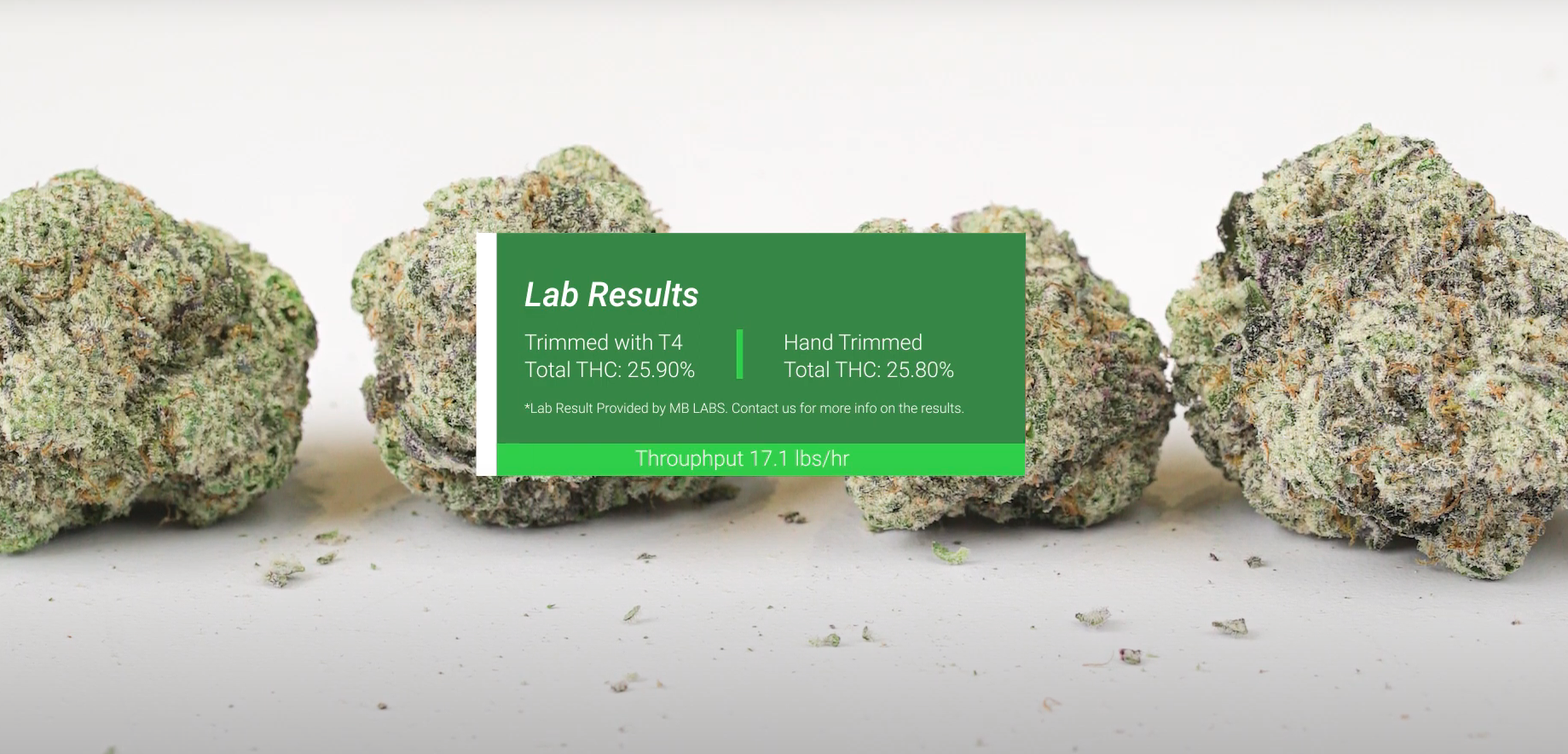

Twister T4 Potency & Lab Tests

We’ll take some Mac 1 and we’ll hand trim it. We want to show the difference in lab results between hand trimmed and machine trim. I predict this flower will lose half a percent in potency vs. a hand trim reference sample. But for me, it’s a very small price to pay for doing 40 pounds by myself especially when you consider time and labour savings.

If you want to get your own Twister T4 setup or have more questions click here to reach out to our reps!