Twister B4 Bucker

Greenhouse Ready Bucker – Available in North America & Europe

Three easy ways to purchase

Have us contact you

Enter your details below and we will get back to you ASAP.

MEET THE

TWISTER

B4 BUCKER

Designed For Your Facility

Quality Assurance

Industry Best Performance

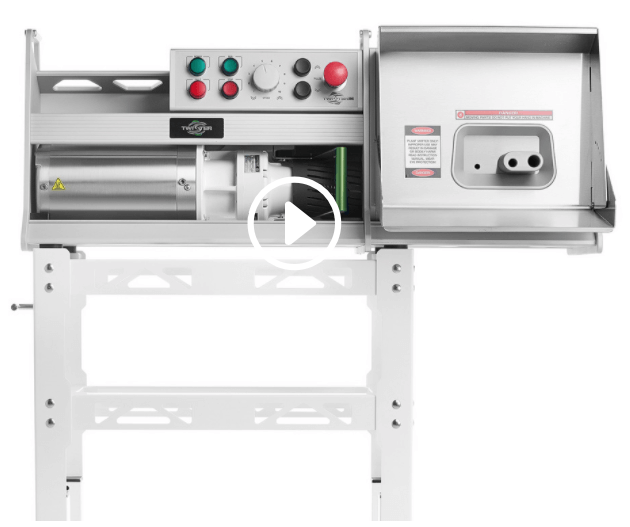

Product Video

Product Specs

Downloads

Designed for Your Facility

The B4 ‘Bucker’ was engineered to meet the needs of everyone that contributes to a successful harvest at your facility. Click the [+] to the right to sort and prioritize the key features to match common roles within your facility.

Features:

- 150+ lbs/hr throughput (speeds of up to 30 ft/sec)

- Quick and easy changeouts with removable cartridges

- Patent-pending “Active Gearing” drivetrain reduces jams and downtime

- Washdown Rated (Pressure washable)

- SafeFeed™ adaptor on the entry holes prevents injury

- Emergency stop. Clear and within reach.

- Easy to use. Ergonomically designed. Easy to load and operate.

- Easy to clean. Breaks down in less than 2 minutes. Easy access to components.

- Minimal training required. Manuals, videos, and tips available on the website.

- Buck dry or fully hydrated.

- GFCI Compatible so you can run it inside your high humidity greenhouse.

Features:

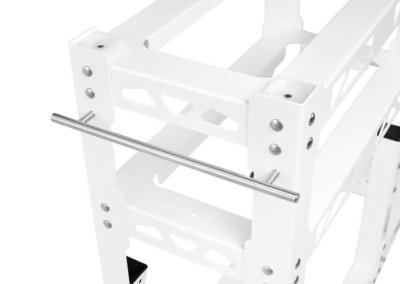

- Enjoy the ability to slide the B4 into your existing GMP facility. No extra work required.

- CE Certified. https://cemarking.net/what-is-ce-marking/

- CSA Compliant. https://www.csagroup.org/service/certification/

- UL Compliant. https://ulstandards.ul.com/

- Complies with requirements for GMP facilities

- The B4 uses tension-adjustable neoprene rubber rollers

- Front and exit shrouds. Adjustable front shroud allows you to customize the height to match your outputs. Exit shroud allows stems to slide off into receptacles.

- Emergency stop. Easy to find, easy to use.

- 304 Stainless throughout with anodized aluminum. The quality Twister is known for.

- Easy to clean. Breaks down in less than 2 minutes. Easy access to components.

Features:

- Ergonomically designed. Flexible enough to run a bench, a stand, or a table.

- Easy to use and operate. Complexity has been removed so it’s simple in, simple out.

- SafeFeed™ adaptor prevents injury. Optional/removable safety device protects fingers from the inner rollers.

- Removable feed cartridges – Quick and easy changeouts. An industry-first. Swap out cartridges after a strain is complete and slide in a new QA approved one. Zero downtime.

- Patent-pending gearing system reduces jams and downtime. Adjusts on-the-fly to the variability in stem sizes.

- Adjustable speed to match your process. 10 speed setting to match your bucking process to your overall production.

- Pulse speed controls to burst in forward and reverse. All controls are in one easy place.

- Forward / Reverse

- Emergency stop. Easy to find, easy to use.

Features:

- Easy to clean. Breaks down in less than 2 minutes. Easy access to components.

- Removable front and exit shrouds. Adjustable front shroud allows you to customize the height to match your outputs. Exit shroud allows stems to slide off into receptacles.

- Removable feed cartridges – Quick and easy changeouts. An industry-first. Swap out cartridges after a strain is complete and slide in a new QA approved one. Zero downtime.

- 304 Stainless throughout with anodized aluminum. The quality Twister is known for.

- The B4 uses tension-adjustable neoprene rubber rollers

- Washdown Rated (Watertight) / IP69K and IP66K. Pressure washable

- No tools needed for disassembly

- Minimal small parts

Greenhouse Ready

GFCI compatible. The B4 Hemp Bucker can be safely used in a wet area.

Quality Assurance Like Never Before

Twister harvesting equipment is used by over 70% of the world’s largest producers. The B4 ‘Bucker’ was designed to meet the most stringent QA programs available. What makes the B4 Hemp Bucker really different? Plain and simple – Swappable Cartridges. We feel this tech is a game changer for commercial cannabis and QA departments. Finished with a specific strain? Simply swap in a QA approved cartridge and you’re back up and running. Zero downtime. #gamechanger

Powerful Non-Stop

Performance

The B4 ‘Bucker’ is designed to deliver non-stop performance under the most demanding conditions known to commercial cannabis. An industry first, the B4 ‘Bucker’ uses an “Active Gearing” system that allows the B4 cannabis bucking machine to process stems up to 3/4” in diameter at speed rates of 150+ lbs/hr–no jams!

AVAILABLE IN

EUROPE

PRODUCT VIDEOS

DOWNLOADS

Cut Sheet

NA – EnglishEU – English

Spanish

Italian

Portuguese

Albanian

Brochure

EnglishOrder your Twister B4 Today