In the ever-evolving landscape of industrial production, the implementation of advanced vision systems for quality grading has been a game-changer. Industries such as agriculture, food processing, and consumer packaged goods have long leveraged these technologies to enhance efficiency, product quality, and customer satisfaction. However, one burgeoning industry where such technological integration remains nascent is the cannabis sector. This article delves into how automated grading systems, exemplified by innovations like Marvel AI, can revolutionize quality control in the cannabis industry, much like they have in other sectors.

The Current State of Quality Control in Various Industries

In industries like agriculture and food processing, automated vision systems have profoundly impacted quality control. For instance, in the fruit sorting process, these systems enable the grading of products based on size, color, and defect detection, significantly reducing labor requirements. A study by the University of California found that automated sorting systems could be up to 100 times faster than manual sorting while maintaining accuracy. This transition not only results in labor savings but also ensures a consistently high-quality product, leading to increased customer satisfaction and higher brand equity.

Low-grade almonds vs high-grade optically sorted almonds

Standard blueberries vs optically sorted blueberries

Similarly, in the consumer packaged goods industry, automated vision systems inspect products for packaging defects, label accuracy, and more. A report from the Packaging Machinery Manufacturers Institute indicated that such technologies could reduce packaging errors by up to 90%, translating into lower customer complaints and enhanced brand loyalty.

Contrasting Cannabis Industry with Others

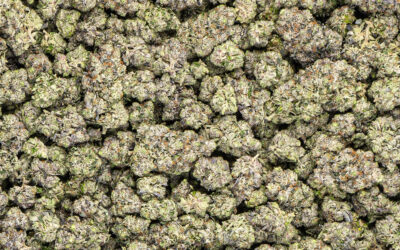

Despite the cannabis industry’s rapid growth, it lags in integrating these advanced vision systems for quality control. The traditional method of grading cannabis often relies on subjective human assessment, which is not only time-consuming but also inconsistent. The lack of standardized, automated grading systems leads to variability in product quality, impacting customer trust and brand reputation.

Manual flower grading

The Value of Automated Grading in Cannabis

Labor Savings

Automated vision systems offer significant labor savings. In the cannabis industry, where the grading and sorting process is intricate due to the nature of the product, these systems can perform tasks at a speed and accuracy that is unachievable by human labor.

Improved Quality

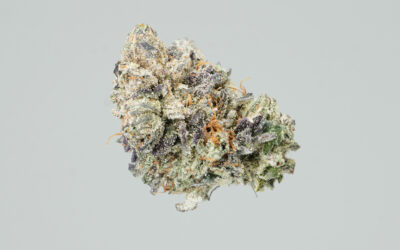

These systems ensure that every square millimeter of cannabis flower is inspected for quality metrics like trichome density, color, size, and potential defects. This thorough inspection guarantees a consistently high-quality product, a crucial factor in an industry where product quality directly influences consumer preference.

Higher Customer Satisfaction

Automated grading systems ensure that fewer defects reach customers, thereby significantly boosting customer satisfaction. In the cannabis industry, where product efficacy and safety are paramount, delivering defect-free products is essential.

Higher Value and Custody Transfer

With fewer defects and higher quality, cannabis producers can command a higher sale price. Moreover, at the wholesale level, automated systems facilitate detailed inspection reports, providing transparency and trust in large batch transactions.

Higher Brand Equity

Consistency in product quality, facilitated by automated grading systems, enhances brand reputation. Consumers and retailers are more likely to trust and prefer brands that consistently deliver high-quality products.

The Secret Weapon: Advanced AI Vision Systems

Several forward-thinking companies in the cannabis industry are quietly employing advanced AI vision systems, like Marvel AI, to gain a competitive edge. These systems, using cutting-edge AI and machine learning algorithms, analyze cannabis flowers at a granular level, offering unparalleled insights and control of product quality.

Marvel AI, for instance, stands as a testament to this technology’s efficacy, employed by some of the industry’s most successful global companies. It represents the pinnacle of technological innovation in cannabis quality control, setting a new standard for precision and efficiency.

Cannabis flower with visual defects (stems, leaf, crows feet) vs cannabis flower without visual defects

Cannabis flower with visual defects (stems, leaf, crows feet) vs cannabis flower without visual defects

The Road Ahead

The integration of automated vision systems in the cannabis industry is not just a leap forward; it is a necessity for those focused automation. The benefits these systems offer – from labor savings to higher customer satisfaction – are too significant to ignore. As the industry grows, the adoption of such technology will likely become the benchmark, separating industry leaders from the rest.

The cannabis sector stands at a pivotal moment, where embracing technological advancements like automated grading systems can redefine its future. It’s a step towards not only higher efficiency and quality but also towards gaining consumer trust and establishing a reputation for excellence.

As we look to the future, it’s clear that automated vision systems will play a crucial role in shaping the cannabis industry. Companies that recognize and adopt this technology will find themselves at the forefront of an industry poised for growth and success.

See the Latest Cannabis News

Built Right, Right From the Jump: Why The T-Zero PRO Is On a Whole Different Level

Intentionally designed. Incredibly effective. T-ZERO PRO delivers.

T-Zero: One Machine, No BS

We’re pushing 125 to 150 lbs/hr on the regular and hitting 200 sometimes

Why We’re Ditching ****** and Rolling Back to Twister

Invested in a setup thinking it would work but it didn’t and switched to Twister

The Ferrari of Trimmers: Twister T-Zero PRO

They pulled the trigger on a T-Zero for their harvest

From Chaos to Control: Why These 2 Producers Bet Big on the Twister T-Zero

Two producers hit the wall during harvest season one overwhelmed, the other burned out…

Unveiling the Future: Marvel Gen 2

We are thrilled to announce the arrival of Marvel Gen 2, the latest...

A Marvel-ous Evolution in Cannabis Consistency

In today's fast-paced market, consumers demand consistency. They...

The Ultimate Nerds Guide to Curing Cannabis

We’ve created multiple guides to curing cannabis to share with you.

The Dawn of a New Quality Era in (Grading) Cannabis

As the cannabis industry blossomed, consumers became ever more...

Elevate Your Cannabis Production Quality: Unlocking the Power of Continuous Employee Training

In today’s cut-throat cannabis market, merely achieving exceptional...

The Complete Guide to GMP Certification in the Cannabis Industry

GMP is a popular topic among the cannabis industry and its...

Cannabis Automation

Why Cannabis Automation is Important Cannabis automation has become...

The Hidden Costs of Commercial Cannabis Trimming Machines

Uncovering the Hidden Costs of Commercial Cannabis Trimming...

How does cannabis dust affect air quality?

As the cannabis industry evolves, many regions are now tightening up...

Trimming Machine Throughput Called Out

As the cannabis industry continues to develop, there is a lack of...

Cannabis Flower Brands with Consistency Win

Cannabis flower brands that are consistent have a much better chance...

How Loud is a Cannabis Trimming Machine?

Are Cannabis Trimming Machines Loud? The noise from cannabis...

How Important is Uptime in Cannabis Processing Facilities?

Understanding the Importance of Uptime in Cannabis Facilities Uptime...

How to Choose a Cannabis Trimming Machine

As the cannabis industry continues to grow, so does the need for...

Cannabis Size Sorting

How is Cannabis sorted? Sorting Cannabis has long been a practice...

Protecting Cannabis Brand Reputation

Grammy Award nominated Don Carlos – Protecting a brand As the owner...

Take the Trim Challenge – Hand Trim vs Twister

Think you have what it takes? One of the images below is trimmed by...

Trimming Craft Cannabis with Twister T4

*Transcribed from video above The Twister Grow Facility -We don’t...

Twister T4 Trimmer Spotlight and Giveaway

Choosing the right trimming machine for your cannabis depends on...

What to Consider when Drying and Curing Cannabis

Drying can be one of the most challenging parts of the cannabis...

Behind The Harvest – Ep 01 w/ Justin Cooper of Growing Exposed

In the inaugural episode of Behind The Harvest, Paul is joined by a...

Keirton Named One of Canada’s Top Small and Medium Employers for 2021

It’s with immense pride that we announce that Keirton has been named...

Cannabis Growth Considerations: How to Prevent Post-Harvest Rot

After a lengthy growing season, you’re finally harvesting your crop...

How to Trim Cannabis Plants: Ensuring Cannabinoid Potency and Quality

The quest for high quality cannabinoids doesn’t end when the plant...

Global CBD Statistics 2021

Global CBD Statistics 2021 CBD oil is most popular in the United...

Marijuana Statistics USA 2021

As you’re probably already aware, different states have very...

Product Spotlight: Twister T2

| Choosing the right machine for your cannabis trimming depends...

Cooked With Cannabis’ Review

Photo Courtesy of Netflix Television viewers have always had a bevy...

Marijuana Legalization in Canada and the USA

Cannabis is fully legalized in Canada and in some states in the USA....

Forbes Feature : CEO Jay Evans

Keirton CEO Jay Evans is taking his passion for innovation, trimming...

Differences Between Marijuana and Hemp

Cannabis, marijuana, and hemp are commonly used interchangeably...

Difference between THC and THCA

Tetrahydrocannabinol (THC) and tetrahydrocannabinolic acid (THCA)...

Cannabis Market Trends During COVID-19

The outbreak of the 2020 Coronavirus has undoubtedly taken a toll on...

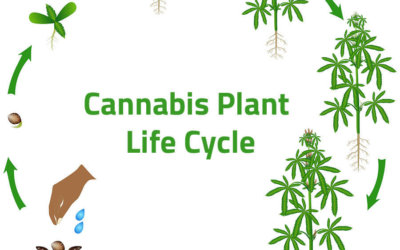

From Seed to Bud: The Plant Life Cycle of Cannabis

The popularity of marijuana plants is rife at different...

Cannabis as a Superfood

Cannabis is rich in natural nutrients that can boost the immune...

Starting your First Grow: When to Trim Your Cannabis

Over the years, cannabis trimming has been a controversial topic...

What to do with Cannabis Trim

Cannabis trim is a term referring to all waste obtained after...

The Best 5 Trimmers for All Your Needs

Trimming marijuana after harvesting is a delicate process that...

How to Maximize Cannabis Yields

Yield is not all about the amount of cannabis harvested,...

Wet Vs Dry Trimming

Bud trimming refers to removing all unwanted plant materials around...

How to Dry Trim

Dry trimming cannabis is a crucial step in determining the quality...

Product Spotlight : Batchone Dry Trimmer

Product Spotlight : Batchone Dry Trimmer Growing cannabis takes a...

How to Get the Most Profit from your Hemp Harvest

If you haven’t already, it’s time to start thinking about harvesting...

The Power of Automation for Harvesting Cannabis: Cultivate Podcast Ep. 10

In May 2018, while attending Lift Expo in Toronto, we sat down to...

Cannabis Trimming Tips: How Dry is Dry?

LEARNING WHEN TO DRY TRIM IS A HIGHLY UNDERRATED SKILL. Like really,...