The Complete Guide to GMP Certification in the Cannabis Industry

GMP is a popular topic among the cannabis industry and its producers. Are you aware of GMP? Are you familiar with GMP certification and processes for cannabis cultivation and manufacturing? Is GMP certification right for you? Do you need GPP, GaCP GMP, cGMP, or EU GMP? The dissemination of information and resources on GMP in relation to cannabis cultivation is haphazard and perplexing. However, as an equipment manufacturer who has been supporting customers with GMP certification for years, we’re here to help! We understand GMP and have broken down the confusing nuances here, in a simple yet comprehensive guide on all things GMP.

What is GMP?

GMP stands for Good Manufacturing Practice. It is a set of guidelines and regulations that ensure the quality and safety of pharmaceutical, food, and medical devices and products. GMP frameworks regulate the manufacturing, handling, cleaning, quality assurance, and packaging processes in facilities and the products they produce. The regulations and procedures required under GMP ensure that products are manufactured in a consistent, controlled, and standardized manner, conforming to established quality standards, while minimizing risk to the end-user.

In simple terms, GMP guarantees that a product is what it is supposed to be and nothing else.

What is GMP certification?

GMP certification is awarded to producers who have demonstrated that they abide to the guidelines and regulations for producing products according to GMP. It is important to note that there is no such thing as GMP certified equipment. Instead, there is equipment that has been designed to meet the demands of a GMP facility – more on this later.

Who regulates GMP certification?

GMP rules and guidelines are developed by regulatory agencies that oversee their regions, and include Health Canada, the US Food and Drug Administration (FDA) and the World Health Organization (WHO). While the principles of GMP are universal, each agency may have specific requirements and guidelines that manufacturers must follow to ensure compliance within their regulations. Further, manufacturers require certification by each agency overseeing regions that they plan to sell their products into. For example, a manufacturer located in Canada, who is looking to sell products in both Canada and Germany, would require GMP certification by the agencies that oversee each region.

How does GMP relate to the Cannabis industry?

Regardless of the licensing authority, product category, or form, cannabis can be classified as a drug in many regions. It is often subject to the various regulations and guidelines governing drugs and pharmaceuticals, including GMP certification. As a result, the application of GMP for medicinal cannabis is used in many jurisdictions worldwide, including Canada, the United States, Australia, New Zealand, Japan, and the European Union. Due to these regulations, cannabis produced in a GMP facility is scrutinized significantly more for safety, quality, and consistency than cannabis produced in a non-GMP facility. Implementing GMP principles in cannabis harvesting and production guarantees that the final product is not only safe for consumption, but also consistent each time it is purchased by the end-user.

Do I need GMP Certification in my cannabis facility?

Without exception, legislation governing the production of cannabis requires a certain level of quality assurance. However, it does not always require GMP certification. The requirement for GMP certification is ultimately dependent on the regions that the cannabis is produced in or being exported to. Here are a few examples of where GMP is required:

- Any manufacturer producing or exporting into the EU market must have EU GMP certification.

- Any manufacturer producing or exporting recreational cannabis into Canada must have GPP certification.

On the other hand, there are many reasons why you may want to consider GMP certification.

While some regulatory authorities presently do not require GMP certification for cannabis products, it is probable that such certification will be mandatory for producers in the future. For example, if the US legalizes cannabis federally, cGMP will likely be required for production facilities. Getting ahead of that requirement may be something to consider.

Moreover, in business-to-business cannabis sales, some distributors and producers insist on a GMP certificate from their product suppliers as consumers are increasingly demanding that products display GMP certification.

Additionally, lacking EU GMP certification could result in international producers losing sales opportunities. Holding GMP certification enhances the prospects for sales in highly regulated markets, particularly for export, and assures customers that the product satisfies the highest standards.

What is GPP, cGMP, WHO GMP, EU GMP, GaCP?

GPP stands for Good Production Practice. It is the quality standard for Canadian Licensed Producers required by Health Canada who are producing cannabis for the Canadian market. It is much less stringent than GMP, and typically only requires that the producer has Standard Operating Procedures (SOPs), and programs for sanitation and recalls.

cGMP stands for Current Good Manufacturing Practice. It is the regulatory standard overseen by the US FDA. Since cannabis is federally illegal in the USA, there is no federal regulations for cGMPs in the cannabis industry for American producers.

WHO GMP is the GMP standard developed by the WHO. This GMP standard has been used as the basis for many other region’s GMP regulations. It is also the standard followed by hundreds of countries around the world that may not have their own standard.

EU GMP, or European Union GMP, are GMP guidelines developed by the European Medicines Agency (EMA). EU GMP regulations for cannabis production are known to be the strictest globally. Like SOPs, sanitation and recall programs from GPP above, EU GMP also requires supplier and equipment qualifications, raw material controls, validations, and a host of other requirements that we’ll dive deeper into throughout this guide.

GaCP stands for Good Agricultural and Collecting Practice. GaCP was developed by the WHO to improve the quality of medicinal plants used in herbal medicines and is often regarded as less stringent that GMP. It follows similar principles as GMP yet focuses on pre-harvest and early post-harvest phases. In cannabis production, this is often the point at which the flower has been dried for further processing. Depending on the processes carried out in a particular facility, GaCP may be all that is required.

While the above list doesn’t cover all the variations of GMP, it encompasses the most common encountered in cannabis production.

How long does it take to get my cannabis facility GMP certified?

The time it takes to get a cannabis facility GMP certified can vary depending on several factors.

First off, it depends on the readiness of the facility to meet GMP requirements. If the facility already has well-established quality management systems (QMS), standard operating procedures (SOPs) in place, and equipment that satisfies GMP requirements, it may take less time to achieve GMP certification. If the facility has been operating without a QMS or SOPs, certification can take months to even years. A GMP GAP assessment will help determine where improvements need to be made and should be performed by experienced regulatory experts.

Next, timing for the certification process will vary depending on the certification body. Some regions have very stringent certification bodies and auditors, while other regions do not. This process is analogous to obtaining a business license or construction permit – in some jurisdictions this is quick and painless, while others it can be slow and dreadful.

Lastly, timing depends on the size of the facility and the various manufacturing processes taking place. Large, vertically integrated facilities manufacturing a lot of products will have a longer GMP journey than small, focused facilities.

Regardless of the situation, the certification body will conduct an audit of the facility to assess its compliance with their GMP standards. Deficiencies or non-conformities identified during the audit will need to be addressed before certification can be granted. It is also important to note that GMP certification is not a one-time event. Facilities must maintain ongoing compliance with GMP standards and undergo regular audits to maintain their certification.

How much does it cost to get my facility GMP certified?

Like timing, the cost of getting a cannabis facility GMP certified can vary depending on several factors. The size of the facility, the complexity of the operation, the manufacturing equipment selected, and the certification body chosen will all impact the cost. In general, the cost can range from tens of thousands to hundreds of thousands of dollars.

Some of the costs associated with GMP certification may include hiring consultants to assess and help prepare the facility for certification during the GAP assessment, implementing necessary changes to meet GMP standards – including a QMS and equipment upgrades – conducting internal audits, and paying certification fees to the certification body. The cost may also include ongoing maintenance of the GMP system to ensure continued compliance with the standards.

It’s important to note that while the cost of GMP certification may be significant, the benefits of certification can include improved product quality, increased customer confidence, and expanded market access. However, be sure that these benefits outweigh the cost as your region may never require it. At the same time, it’s possible, and even often advisable, to begin implementing many of the GMP requirements.

What are the basics of GMP in Cannabis Processing?

GMP certification for cannabis processing involves the following basic guidelines:

- Quality Management System (QMS): The cannabis processing facility should have a QMS in place that documents all procedures and practices used to ensure the quality of the products.

- Standard Operating Procedures (SOPs): The facility must have SOPs in place for all aspects of cannabis processing, including cultivation, harvesting, drying, trimming, curing, extraction, packaging, labeling, storage, and destruction. These SOPs should be regularly reviewed, updated, documented, and followed.

- Staff Training: All employees involved in the cannabis processing facility should receive regular training on GMP guidelines, their QMS, SOPs, and other relevant topics. Records of training should be maintained.

- Facility and Equipment: The processing facility should be designed and maintained to ensure that it is clean, safe, and suitable to produce cannabis products. Equipment should be calibrated and maintained regularly to ensure accurate and consistent results. Equipment must also be easy to clean, not introduce extraneous materials to the product, and used for its intended purpose.

- Documentation: All aspects of the cannabis processing, including testing, should be fully documented to ensure traceability and accountability.

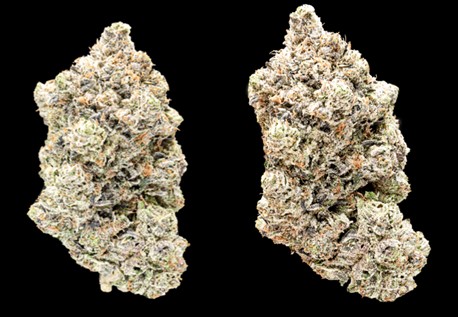

- Quality Control Testing: Products should be regularly tested to ensure that they meet the required quality standards, including potency, purity, and consistency.

- Product Tracking: A system should be in place to track the products throughout the entire production process, from cultivation to distribution.

These guidelines are not exhaustive and may vary depending on the jurisdiction and the specific product being manufactured.

What are the key aspects when selecting GMP cannabis processing equipment?

When selecting equipment for cannabis processing in compliance with GMP, several key aspects need to be considered:

- Material of construction: GMP standards require that equipment used in the production of cannabis products should be made of materials that are non-toxic, are cleanable, and are non-reactive with the product. The materials should also not flake off or wear away, introducing extraneous materials to the product. Commonly accepted materials for GMP processing equipment include stainless steel, glass, silicone, and plastics recognized with the above properties. Stainless steel is a common material used in GMP equipment due to its durability, resistance to corrosion, and ease of cleaning. Glass is also a good option for equipment that meets the product, as it is non-reactive and easy to sterilize. Anodized aluminum can be an acceptable material for contact surfaces of GMP processing equipment. However, it is important to note that certain chemicals used in anodizing may not be acceptable for use in contact with certain products. Food-grade plastics are acceptable and should be suitable for high-temperature cleaning and sanitation. In addition, the plastic must not shed particles or fibers that could contaminate the product or the processing environment. Plastic is difficult to detect in cannabis, unlike metal that can be detected with metal detectors. Avoid materials that can corrode, react with, or leach into the product, Also, avoid materials that are not durable and coatings that could flake off – painted, powder-coated, or other coated materials are not recommended.

- Design and construction: The equipment should be designed and constructed in a way that minimizes the risk of contamination, allows for proper cleaning, sanitization and ensures consistent performance. It is especially important that the equipment is designed with smooth surfaces that are free of crevices or pockets where product can accumulate, and bacteria can thrive. This is critical in contact surfaces. Contamination and costly recalls are common with equipment that cannot be properly sanitized.

- Validation and qualification: The equipment should be validated and qualified to ensure it meets the required specifications, functions as intended, and used in accordance with its intended use. Look for suppliers who can help support the development of these documents as they’ll often have the majority of what is needed for your processes.

- Maintenance and calibration: The equipment should be maintained and calibrated regularly to ensure it continues to operate effectively and within specifications.

- Documentation: Documentation of all processes, including equipment selection, maintenance, calibration, and validation, should be kept as part of GMP compliance.

- Training: Personnel operating the equipment should be trained and qualified to ensure proper operation and maintenance in accordance with GMP requirements.

By considering these key aspects when selecting equipment for cannabis processing, GMP compliance can be ensured, leading to safe and high-quality products for consumers. Keirton products were designed with these aspects in mind.

What is Equipment Qualification and Validation?

Qualification and Validation are important processes used to ensure that equipment used in the manufacturing process meets specific quality and regulatory requirements.

Qualification is a process that ensures that equipment is suitable for its intended use and meets pre-established performance specifications. It involves testing and verifying equipment functions, design, installation, operation, and maintenance to ensure that it meets the intended performance requirements. Qualification is typically divided into four stages: design qualification (DQ), installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ).

- Design Qualification (DQ): Design Qualification is the first stage of equipment qualification, which ensures that the equipment design meets all the required standards and specifications. It includes the review and approval of equipment design drawings, specifications such as capacity or throughput, and any other documentation that defines the equipment’s intended use, performance, and functionality. This stage helps to ensure that the equipment is suitable for its intended purpose and meets the required quality and safety standards.

- Installation Qualification (IQ): Installation Qualification involves verifying that the equipment is installed correctly, and it meets the specifications and requirements outlined in the DQ. This stage includes checking the equipment’s installation location, power supply, and connections. It also includes ensuring that the equipment is installed according to the manufacturer’s instructions, and any necessary environmental controls are in place.

- Operational Qualification (OQ): Operational Qualification is the stage where equipment performance is tested to ensure that it functions as intended. This stage includes testing the equipment’s performance under various operating conditions to ensure that it meets the established specifications. It includes testing the equipment’s functionality, safety features, and control systems.

- Performance Qualification (PQ): Performance Qualification is the final stage of equipment qualification, where the equipment is tested to ensure that it can consistently perform within the specified range of parameters. This stage includes testing the equipment’s performance under actual operating conditions, and it is typically conducted over a more extended period.

Each of the above qualifications are pre-established in qualification documentation.

Validation, on the other hand, verifies that equipment, processes, and systems can consistently produce products that meet pre-established specifications and quality standards. Validation is typically divided into three stages: process validation, analytical method validation, and cleaning validation.

- Process Validation: Process validation is the stage where the manufacturing process is verified and validated to ensure that it can consistently produce products that meet the pre-established quality standards. This stage includes identifying critical process parameters, monitoring, and controlling these parameters, and verifying that the process can produce consistent and high-quality products. The goal of process validation is to ensure that the manufacturing process is robust and can consistently produce products that meet the required quality standards.

- Analytical Method Validation: Analytical method validation is the stage where analytical methods used to measure the quality and purity of the products are verified and validated. This stage includes determining the accuracy, precision, specificity, and linearity of the analytical methods used to ensure that they can consistently measure the quality attributes of the product. The goal of analytical method validation is to ensure that the analytical methods used to measure the product’s quality are reliable and accurate. This can be a significant challenge with cannabis as matching THC levels from harvest to harvest is difficult.

- Cleaning Validation: Cleaning validation is the stage where the cleaning procedures used to clean and sanitize the equipment and manufacturing facilities are validated to ensure that they can effectively remove product residues and contaminants. This stage includes identifying the equipment and areas that require cleaning, developing and validating cleaning procedures, and verifying that the cleaning procedures can effectively remove product residues and contaminants. The goal of cleaning validation is to ensure that the equipment and manufacturing facilities are clean and free from contamination, which could affect the quality of the product.

What’s the difference between cleaning and sanitation?

While cleaning and sanitation, or sanitizing, are often used interchangeably, they are not the same thing.

Cleaning involves removing deposits on surfaces, including dirt, dust, and other organic deposits. Cleaning is the first step in a cleansing process, and often includes the use of soaps, detergents, and degreasers.

On the other hand, sanitizing involves killing bacteria that may be present on the surface after it has been cleared during the cleaning step. Sanitizers often include isopropyl alcohol, ethanol, and hydrogen peroxide.

How important is cleaning and sanitation in a GMP facility?

Cleaning and sanitation are critical aspects of any GMP facility, including cannabis processing facilities. It is important to ensure that all equipment, surfaces, and areas that come into contact with the cannabis products are thoroughly cleaned and sanitized to prevent contamination and maintain product quality and safety.

Inadequate sanitation can lead to the growth of microorganisms and other pathogens, which can cause contamination and spoilage of products. This can result in significant financial losses for the facility, damage to the facility’s reputation, and potential harm to consumers. This can also lead to very costly recalls.

Proper sanitation procedures, including the use of appropriate cleaning agents, sanitizers, and cleaning equipment, are essential to maintaining a clean and safe environment in a GMP facility. Sanitation should be an ongoing process and should be performed regularly to prevent the buildup of contaminants.

When cleaning cannabis processing equipment in a GMP facility, the common steps include:

- Pre-cleaning assessment: Before starting the cleaning process, it is crucial to assess the equipment to be cleaned to determine the appropriate cleaning method and the level of cleaning required.

- Disassembly: The equipment should be disassembled to the extent necessary to allow for thorough cleaning.

- Dry cleaning: Dry cleaning methods, such as vacuuming or brushing, can be used to remove any loose debris or dust from the equipment.

- Wet cleaning: Wet cleaning methods involve using water, soap, detergent, and degreasers to remove any remaining contaminants. The cleaning solution should be prepared according to the manufacturer’s instructions and the concentration should be checked to ensure effectiveness.

- Rinsing: After wet cleaning, the equipment should be thoroughly rinsed with clean water to remove any remaining cleaning solution and debris.

- Sanitizing: Once the equipment has been cleaned and rinsed, it should be sanitized using an appropriate sanitizer, such as isopropyl alcohol, ethanol, hydrogen peroxide, chlorine, or quaternary ammonium compounds. The sanitizer should be applied according to the manufacturer’s instructions and the contact time should be sufficient to ensure effective sanitation.

- Drying: After sanitizing, the equipment should be air-dried or dried using a clean, lint-free cloth.

- Reassembly: Once the equipment is clean, sanitized, and dry, it can be reassembled and put back into service.

- Verification: Finally, it is important to verify the effectiveness of the cleaning and sanitation process by testing the equipment or surfaces for the absence of contaminants or microbial growth.

How do I verify my cannabis processing equipment is clean and sanitized?

There are two common methods for verifying that cannabis processing equipment does not contain microbials after sanitizing: adenosine triphosphate (ATP) swabs and laboratory testing.

ATP swabs are a quick and affordable method for verifying cleanliness and typically the first line of defense. ATP is a molecule found in all living cells, so its presence indicates the presence of microorganisms. ATP swabs are used to sample surfaces on the equipment, and the swab is then inserted into a handheld device that measures the level of ATP present. If the level is below a certain threshold, the equipment is considered sanitized.

Laboratory testing involves taking samples from various surfaces on the equipment and sending them to a microbiology lab for analysis. The lab will culture the samples and identify any microorganisms present. This method is highly accurate, but it can be time-consuming and expensive.

It’s important to note that while ATP swabs are a useful tool for verifying cleanliness, they do not provide information about the specific types of microorganisms present. For this reason, laboratory testing may still be necessary in certain situations, such as when there is a history of microbial contamination or when producing products for immunocompromised individuals.

In Summary

The application of GMP is essential to ensure the safety and quality of a food or drug product for human consumption. By adhering to GMP guidelines, manufacturers can produce high-quality, safe products that meet established quality standards and comply with regulatory requirements.

GMP certification requires implementation of a QMS, SOPs, staff and operator training, equipment and facility considerations, documentation, quality control testing and product tracking. Becoming GMP certified can offer several benefits for a cannabis processing facility, including providing assurance to regulators, customers, and investors that the facility meets the required quality and safety standards; and it can help the facility to operate more efficiently by identifying areas for improvement and ensuring consistency in processes and products. However, the process of becoming GMP certified can be time-consuming and expensive, requiring significant investments in training, equipment, and documentation. Furthermore, the stringent requirements of GMP can limit the flexibility and creativity of the facility’s operations, which may hinder innovation and product development. Ultimately, the decision to pursue GMP certification should be based on a careful consideration of your regional requirements, as well as the costs and benefits for the facility and its stakeholders.

If you need assistance with your GMP journey, including selecting the right equipment, feel free to reach out to our team.

See the Latest Cannabis News

Built Right, Right From the Jump: Why The T-Zero PRO Is On a Whole Different Level

Intentionally designed. Incredibly effective. T-ZERO PRO delivers.

T-Zero: One Machine, No BS

We’re pushing 125 to 150 lbs/hr on the regular and hitting 200 sometimes

Why We’re Ditching ****** and Rolling Back to Twister

Invested in a setup thinking it would work but it didn’t and switched to Twister

The Ferrari of Trimmers: Twister T-Zero PRO

They pulled the trigger on a T-Zero for their harvest

From Chaos to Control: Why These 2 Producers Bet Big on the Twister T-Zero

Two producers hit the wall during harvest season one overwhelmed, the other burned out…

Automated Grading in Cannabis: Revolutionizing Quality Control with Advanced Vision Systems

Introducing a state-of-the-art automated cannabis grading machine, revolutionizing quality control.

Unveiling the Future: Marvel Gen 2

We are thrilled to announce the arrival of Marvel Gen 2, the latest...

A Marvel-ous Evolution in Cannabis Consistency

In today's fast-paced market, consumers demand consistency. They...

The Ultimate Nerds Guide to Curing Cannabis

We’ve created multiple guides to curing cannabis to share with you.

The Dawn of a New Quality Era in (Grading) Cannabis

As the cannabis industry blossomed, consumers became ever more...

Elevate Your Cannabis Production Quality: Unlocking the Power of Continuous Employee Training

In today’s cut-throat cannabis market, merely achieving exceptional...

Cannabis Automation

Why Cannabis Automation is Important Cannabis automation has become...

The Hidden Costs of Commercial Cannabis Trimming Machines

Uncovering the Hidden Costs of Commercial Cannabis Trimming...

How does cannabis dust affect air quality?

As the cannabis industry evolves, many regions are now tightening up...

Trimming Machine Throughput Called Out

As the cannabis industry continues to develop, there is a lack of...

Cannabis Flower Brands with Consistency Win

Cannabis flower brands that are consistent have a much better chance...

How Loud is a Cannabis Trimming Machine?

Are Cannabis Trimming Machines Loud? The noise from cannabis...

How Important is Uptime in Cannabis Processing Facilities?

Understanding the Importance of Uptime in Cannabis Facilities Uptime...

How to Choose a Cannabis Trimming Machine

As the cannabis industry continues to grow, so does the need for...

Cannabis Size Sorting

How is Cannabis sorted? Sorting Cannabis has long been a practice...

Protecting Cannabis Brand Reputation

Grammy Award nominated Don Carlos – Protecting a brand As the owner...

Take the Trim Challenge – Hand Trim vs Twister

Think you have what it takes? One of the images below is trimmed by...

Trimming Craft Cannabis with Twister T4

*Transcribed from video above The Twister Grow Facility -We don’t...

Twister T4 Trimmer Spotlight and Giveaway

Choosing the right trimming machine for your cannabis depends on...

What to Consider when Drying and Curing Cannabis

Drying can be one of the most challenging parts of the cannabis...

Behind The Harvest – Ep 01 w/ Justin Cooper of Growing Exposed

In the inaugural episode of Behind The Harvest, Paul is joined by a...

Keirton Named One of Canada’s Top Small and Medium Employers for 2021

It’s with immense pride that we announce that Keirton has been named...

Cannabis Growth Considerations: How to Prevent Post-Harvest Rot

After a lengthy growing season, you’re finally harvesting your crop...

How to Trim Cannabis Plants: Ensuring Cannabinoid Potency and Quality

The quest for high quality cannabinoids doesn’t end when the plant...

Global CBD Statistics 2021

Global CBD Statistics 2021 CBD oil is most popular in the United...

Marijuana Statistics USA 2021

As you’re probably already aware, different states have very...

Product Spotlight: Twister T2

| Choosing the right machine for your cannabis trimming depends...

Cooked With Cannabis’ Review

Photo Courtesy of Netflix Television viewers have always had a bevy...

Marijuana Legalization in Canada and the USA

Cannabis is fully legalized in Canada and in some states in the USA....

Forbes Feature : CEO Jay Evans

Keirton CEO Jay Evans is taking his passion for innovation, trimming...

Differences Between Marijuana and Hemp

Cannabis, marijuana, and hemp are commonly used interchangeably...

Difference between THC and THCA

Tetrahydrocannabinol (THC) and tetrahydrocannabinolic acid (THCA)...

Cannabis Market Trends During COVID-19

The outbreak of the 2020 Coronavirus has undoubtedly taken a toll on...

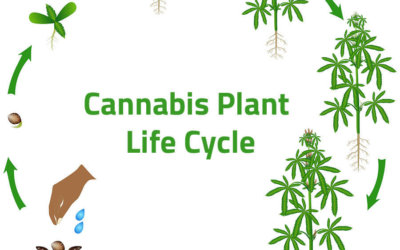

From Seed to Bud: The Plant Life Cycle of Cannabis

The popularity of marijuana plants is rife at different...

Cannabis as a Superfood

Cannabis is rich in natural nutrients that can boost the immune...

Starting your First Grow: When to Trim Your Cannabis

Over the years, cannabis trimming has been a controversial topic...

What to do with Cannabis Trim

Cannabis trim is a term referring to all waste obtained after...

The Best 5 Trimmers for All Your Needs

Trimming marijuana after harvesting is a delicate process that...

How to Maximize Cannabis Yields

Yield is not all about the amount of cannabis harvested,...

Wet Vs Dry Trimming

Bud trimming refers to removing all unwanted plant materials around...

How to Dry Trim

Dry trimming cannabis is a crucial step in determining the quality...

Product Spotlight : Batchone Dry Trimmer

Product Spotlight : Batchone Dry Trimmer Growing cannabis takes a...

How to Get the Most Profit from your Hemp Harvest

If you haven’t already, it’s time to start thinking about harvesting...

The Power of Automation for Harvesting Cannabis: Cultivate Podcast Ep. 10

In May 2018, while attending Lift Expo in Toronto, we sat down to...

Cannabis Trimming Tips: How Dry is Dry?

LEARNING WHEN TO DRY TRIM IS A HIGHLY UNDERRATED SKILL. Like really,...