T2 Frequently Asked Questions

The Twister T2 is engineered to minimize trichome loss with its Gentle Tumble and precise, food-safe nitrided blades and the Twister proven process. The design prioritizes gentle handling and a fast process (about 20-30 seconds per batch), reducing the time buds are exposed to friction compared to other machines or prolonged hand trimming346. Proper adjustment and operation are key to preserving trichome integrity.

2. Will the T2 “eat” my weed or cause excessive product loss?

When used correctly, the T2 does not “eat” your buds. Its QuickClick™ technology allows you to fine-tune the cut height for minimal loss6. However, if blades are dull or the machine is not cleaned regularly, you may see more trim or smaller buds passing through. Routine maintenance and proper setup prevent excessive product loss2.

3. How does the tumbling action affect bud structure and density?

The T2’s gentle tumbling action is designed to maintain bud structure and density. The process is quick (30 seconds per batch), so there’s minimal opportunity for buds to be beaten up or flattened34. Overloading or running the machine too long can cause damage, so following recommended batch sizes and timing (incline) is important.

4. Can the Twister T2 handle large, sticky, or dense buds without jamming or clogging?

Yes, the T2 is built for commercial throughput and can handle dense, sticky buds. However, sticky resin can build up on blades and tumblers, especially in warm environments. It’s crucial to trim in an controlled environment that is similar to a dry room, ~60-65F and 50-60% relative humidity. Regular cleaning and periodic adjustment ensure also correct operation.23. When trimming wet, operators can apply cold water to the machine brush with a spray bottle every few minutes to reduce plant material build up.

5. How much trim do I lose compared to hand trimming?

The T2 is designed to maximize yield and minimize trim loss. With precise adjustment, you can achieve a trim quality close to hand trimming, but some very small pea sized buds or loose material may end up in the trim, as with any machine. Many growers find the trim loss is comparable or even less than with hand crews, especially after dialing in the machine23.

6. Is the trim collected by the T2 suitable for extraction or is it too pulverized?

The T2’s trim is well-suited for extraction. The machine is designed to produce clean, high-quality trim with minimal pulverization, especially when maintained and operated correctly. The optional Trim Saver system helps collect usable trim for further processing improving the quality of the recovered trim by bypassing the fan impeller.34.

7. Does the T2 flatten, bruise, or otherwise beat up my buds?

When operated as intended, the T2 preserves bud shape and structure. Its quick cycle and gentle tumbling minimize bruising and flattening. Overfilling the tumbler or running batches too long can increase the risk of damage, so follow recommended procedures for best results34.

8. How do I prevent popcorn buds or small nugs from getting sucked into the vacuum?

Using the adjustable vacuum and feed rate controls helps reduce the risk of small buds being sucked away. Some loss of very small pea-sized buds is possible, but careful adjustment and monitoring during operation can minimize this issue6.

9. Can I adjust the trimming tightness to avoid over-trimming or under-trimming?

Yes, the T2 features QuickClick™ technology for ultra-precise blade adjustments (0.0009”/0.023mm per click), allowing you to control how tight or loose the trim is6. This lets you tailor the cut to different strains and preferences.

10. How do I dial in the T2 for different strains or moisture levels?

Adjust the blade height, machine incline and feed rate according to the bud size, density, and moisture content. For stickier or wetter buds, slower feed rates and more frequent cleaning may be needed. The T2 is designed for both wet and dry trimming, with separate tumblers with different slot widths to match you style of trim.46.

11. How much labor does the T2 actually save compared to a hand crew?

The T2 can replace a large hand crew, processing up to 35-45 lbs wet or 14-16 lbs dry per hour with one machine, and even more in tandem setups346. This dramatically reduces labor costs and time spent on post-harvest processing.

12. What’s the real throughput per hour for wet vs. dry trimming?

Expect 35-45 lbs per hour for wet trimming and 14-16 lbs per hour for dry trimming with a single T2. Tandem setups can double or triple this output346. Actual results may vary based on strain and operator experience.

13. Is there a learning curve to getting good results with the T2?

Yes, like any precision equipment, there’s a short learning curve. Most operators can achieve excellent results after a few runs, especially with guidance from Twister’s support team and manuals23. Optional field support is available for purchase to have our expert team members visit your facility and train the trainer to make sure you get years of consistent results.

14. How hard is it to clean sticky resin out of the machine?

The T2 is designed for easy cleaning-no tools required, and it’s fully watertight for safe pressure washing346. Resin build-up can be managed with regular quick cleanings during use and thorough washes at the end of each day2.

15. How often do I need to stop for cleaning during a big run?

For best performance, pause every 30-60 minutes to wipe down resin from the blades and tumbler, especially with sticky strains. This prevents gumming up and ensures a consistent cut2.

16. Do I need to break down the T2 for cleaning, or can I wash it in place?

The T2 disassembles in seconds for thorough cleaning, but you can also hose down the watertight components in place. This makes end-of-day cleaning fast and easy346.

17. How durable are the blades and tumblers-do they need frequent replacement?

The T2 uses high-carbon, nitrided steel blades with a lifespan of up to 600 hours, depending on use and maintenance36. Regular cleaning and proper adjustment extend their life. Tumblers are made from durable stainless steel and rarely need replacement under normal use.

18. Will the T2 work for both craft (boutique) and commercial (bulk) harvests?

Yes, the T2 is widely used by both boutique and large-scale commercial growers. Its adjustable settings and gentle handling make it suitable for high-quality craft flower as well as high-volume production34. It’s limited adjustments make it very simple for teams to learn and use to the maximum capabilities.

19. Can the T2 be used for both wet and dry trimming, and what are the pros and cons of each?

The T2 can trim both wet and dry flower. Wet trimming is faster and easier to clean, while dry trimming can preserve structure and better aroma but may require slower feed rates and more care in drying preparation.

20. How does the T2 compare to other trimmers like the CenturionPro or GreenBroz in terms of bud quality?

The T2 is known for its gentle, precise trimming and minimal bud damage, thanks to its patented use of the best available materials, blade geometry and gentle tumble action346. Many growers prefer the T2 for its consistent results and easy cleaning, though every machine has its own strengths.

21. Does the T2 require a specific vacuum or can I use my own?

The T2 is designed to work with the Twister Leaf Collector or the Twister Trim Saver vacuum, which is optimized for airflow and suction. Using the recommended vacuum ensures best results and prevents issues with trim collection6.

22. Can I run multiple T2s in tandem, and is there a bottleneck with the vacuum or conveyors?

Yes, the T2 is built for scalability-multiple units can be run in tandem to increase throughput. The Twister Leaf Collector and conveyor systems are designed to handle the increased load, minimizing bottlenecks456.

23. What’s the best way to load the T2 for even, consistent trimming?

Control the environment as tightly as possible from the drying room right to the trimming room with temperatures and humidities close to that inside the drying room. Feed buds evenly and avoid under/overloading the tumbler. Use a feed conveyor for large runs to maintain a steady input and consistent trim quality45. The optimal fill for the tumbler is ½-2/3 of the diameter area.

24. Are there common operator mistakes that lead to poor results or machine issues?

Common mistakes include under/over drying prior to trimming, under/overloading the tumbler, running the machine too long per batch, neglecting cleaning, and improper blade adjustment. Following the manual and regular maintenance prevent most issues23.

25. How loud is the T2 in operation-will it disrupt my facility?

The T2 is powerful and does generate noise, especially from the vacuum. While not excessively loud for an industrial environment, hearing protection is recommended for operators working nearby for extended periods6.

26. What is the actual ROI for a mid-sized grow using the T2?

Most growers report the T2 pays for itself in a single harvest due to labor savings and increased throughput if upgrading from hand trimming. The exact ROI depends on your scale, but the machine is considered one of the highest-ROI investments in post-harvest processing346.

27. Does Twister offer support or training for new users?

Yes, Twister provides technical support, detailed manuals, and phone assistance. Optional field support is available for purchase to have our expert team members visit your facility and train the trainer to make sure you get years of consistent results

28. What’s covered under the warranty, and how fast is service if something breaks during harvest?

The T2 comes with a comprehensive 3-year warranty covering parts. Twister and its distributors are well known for responsive service and quick parts replacement to minimize downtime6.

29. Are replacement parts and accessories easy to get in Canada and the US?

Yes, Twister has a strong dealer network and parts are readily available in both Canada and the US. Most common parts and accessories can be shipped quickly to minimize downtime36.

30. Can the T2 handle hemp as well as cannabis, especially with tougher stalks and larger nugs?

Yes, the T2 is used by both cannabis and hemp producers. Its powerful motor and durable construction can handle the larger, tougher buds and stalks typical of hemp crops36.

31. What are the technical specifications of the Twister T2?

The Twister T2 operates on 115V/60Hz or 230V/50Hz with a current draw of 15.5A or 8A , respectively. It weighs 215 lbs (97.5kg) and measures 42.5″ (107.9cm) in length, 27.5″ (69.9cm) in width with wheels (20.5″/52.2cm without), and stands 32.5″ (82cm) tall (30.5″/76cm without wheels). The machine features a 1HP (750W) fan-cooled stainless steel blade motor and a 1/30HP (25W) epoxy-coated watertight tumbler motor19.

32. What is the processing capacity of the Twister T2?

The Twister T2 can process up to 35 lbs (16 kg) of wet cannabis per hour or 11 lbs (5 kg) of dry cannabis per hour with a single unit. When configured in tandem with multiple units, productivity increases substantially.

33. Can the Twister T2 trim both wet and dry cannabis?

Yes, the Twister T2 is designed to handle both wet and dry trimming. It comes with a 1/4″ tumbler which can process cannabis at various moisture levels, from 11% to fully hydrated product. An optional 3/16” slot accessory tumbler is available for sale separately.

34. What power requirements does the Twister T2 have?

The T2 requires a 120V, 60Hz power supply with a 20A circuit breaker. It uses a NEMA 5-20P plug and draws 15.5A of current. For extension cords, a minimum 12AWG cord is required, with a maximum length of 50ft/15m. In 50Hz regions, the input power requires 230V, 50Hz power supply with a 10A circuit breaker. The 50Hz versions ship with a CEE 7/7 plug and draw 8A of current.

35. What materials is the Twister T2 constructed from?

The T2 is built with stainless steel and anodized aluminum components. The tumbler is made of 304 stainless steel, and the blades are made of hardened nitrided steel. These materials prevent contamination risks and eliminate the need to constantly replace parts due to paint chips or flaking1118.

Operation and Performance

36. How precise is the trimming with the Twister T2?

The T2 is equipped with QuickClick technology, ensuring extremely precise blade adjustments of up to 0.0009″ (0.023mm) per click. The cut height can be adjusted from .040″ (1mm), allowing for precision trimming that maintains the quality of your product213.

37. How do I set up the Twister T2 for first-time use?

Setup involves placing the T2 on a level surface (preferably Twister Rails), connecting it to power (using the appropriate extension cord), installing safety guards and covers, connecting the vacuum system, and adjusting the tilt as needed. Detailed step-by-step instructions are available in the user manual819.

38. How long does it take to process cannabis through the Twister T2?

The T2 reduces a 20-minute trimming job to just 30 seconds. With 11 StaySharp self-sharpening blades delivering 19,250 cuts per minute, the tumbling time for each batch is less than one minute1318.

39. Can I adjust the trimming precision on the Twister T2?

Yes, the T2 allows for ultra-precise blade adjustments through its QuickClick technology. The blades can be adjusted with great precision (0.0009″/0.023mm per click) to achieve your desired trim quality27.

40. What is the proper way to operate the Twister T2?

Operation involves a sequence of steps: powering on the machine, starting the vacuum, allowing it to reach full speed, activating the blade motor, allowing blades to reach full speed, starting the tumbler motor, and then feeding product into the machine. The T2 user manual provides detailed instructions for safe and effective operation819.

Maintenance and Cleaning

41. How do I clean the Twister T2 after use?

The T2 can be disassembled for cleaning in less than 10 seconds without tools. It features watertight electrical components and motors that allow for complete high-pressure washdown. Regular cleaning is essential to prevent material buildup on the brush and tumbler811.

42. Is the Twister T2 waterproof for cleaning purposes?

Yes, the T2 is the only trimmer on the market that is fully watertight. Its electrical components and motors are designed to withstand complete high-pressure washdown, providing built-in investment protection against water or moisture damage11.

43. What regular maintenance does the Twister T2 require?

Regular maintenance includes cleaning after each use, checking and tightening the blade belt, lubricating moving parts with food-grade lubricants, and inspecting blades and tumbler for wear or damage. The user manual provides a detailed maintenance schedule and procedures8.

44. What tools are required for maintaining the Twister T2?

Maintenance requires specific tools including: 5/32 hex key for belt covers, 7/32 hex key and 5/8 wrench for tumbler adjustment, 3/16 hex key for bed knife and nylon brush, 1/4 hex key and 11/16 wrench for rollers, 5/8 wrench for bed knife adjustment, 7/32 hex key for reel blade belt, and 5/32 hex key and 7/16 wrench for hopper adjustment1.

45. How often do I need to replace parts on the Twister T2?

The T2 is designed for low-cost ownership with durable components. The hardened steel blades require less frequent sharpening than competitors’ products. Replacement parts such as belts, rollers, and brushes may need periodic replacement based on usage volume. A complete list of replacement parts is available from Twister10.

Scalability and Integration

46. Can I connect multiple Twister T2 machines together for increased capacity?

Yes, the T2 is designed to run in tandem configurations. You can connect up to four machines together to increase productivity by more than 2x. With two T2s in tandem, wet trimming capacity increases to 75-85 lbs/hr. With three units, capacity reaches 125-141 lbs/hr, and with four units, up to 220 lbs/hr – all without increasing labor requirements2717.

47. Does the Twister T2 work with conveyor systems?

Yes, the T2 is designed to work seamlessly with Twister conveyor systems. The feed conveyor is placed inside the tumbler, and the QC (Quality Control) conveyor is positioned under the T2 outlet. This integration enables continuous flow and ongoing quality control throughout the trimming process and also improves trimming consistency 817.

48. What is required to scale my trimming operation with the Twister T2?

Scaling involves adding additional T2 units in tandem configuration (end-to-end), incorporating conveyor systems, and potentially adding the Twister Leaf Collector. The modular design allows you to start with one machine and add more as your business grows. Twister Rails are recommended for proper setup of multiple units811.

Quality and Results

49. How does the quality of Twister T2 trimming compare to hand trimming?

While hand trimming has traditionally been considered the standard, it often results in inconsistencies with different workers producing varying results. The T2 provides consistent, standardized results with every batch. Contrary to popular belief, automated machinery like the T2 can give results very close to manual trimming, especially when operators are properly trained5.

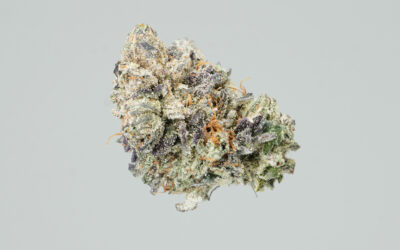

50. Will the Twister T2 damage trichomes or reduce potency?

The T2 is designed to minimize trichome loss through its gentle tumbling action and precise cutting mechanism. The patented blade geometry allows for precision cuts without damaging the buds or their potency. The machine reduces the handling time significantly (from 20 minutes to 30 seconds), which helps preserve trichome integrity1318.

51. What type of trimming finish can I expect from the Twister T2?

The T2 delivers a consistent, professional finish across all your product. With its QuickClick technology allowing for precise blade adjustments and the tumbler’s controlled rotation, you can achieve a uniform appearance that enhances marketability. When combined with the Twister Proven Process, most growers are experiencing near hand trim results with some strains. The system allows for quality control throughout the process, especially when used with conveyor systems217.

Cost and ROI

52. What is the ROI of investing in a Twister T2?

Most T2 customers report achieving a positive ROI in less than one harvest cycle. By dramatically reducing labor costs and increasing throughput, the machine quickly pays for itself. For example, similar trimming machines have shown ROI of over 1,200% for small growers and over 5,200% for large growers within the first year1112.

53. How does the cost of the Twister T2 compare to hiring manual trimmers?

Manual trimming requires multiple workers, extensive labor hours, and introduces variables in quality and consistency. The T2 significantly reduces labor requirements while maintaining consistent quality. Based on similar trimming machine analyses, labor costs can drop by up to 90% when switching from manual to machine trimming 512.

54. How long will it take to recoup my investment in the Twister T2?

Based on similar trimming machine data, the payback period can be as short as 2-4 days for commercial operations. Small growers processing 500 lbs/year may recoup their investment in just 4 days, while larger operations processing 2,000 lbs/year may see payback in as little as 2 days12.

Comparisons

55. How does the Twister T2 compare to the Twister T4?

The T2 offers higher capacity than the T4, processing up to 35 lbs/hr wet (vs. 23 lbs/hr for the T4) and 11 lbs/hr dry (vs. 7 lbs/hr for the T4). The T2 has a larger tumbler diameter (6 inches vs. 5 inches) and a more powerful blade motor (1 HP vs. 0.25 HP). While both are modular, the T2 includes a wheeled stand for facility transport, while the T4 is more portable for car transport16.

56. How does the Twister T2 compare to other trimming machines on the market?

The T2 stands out as the only trimming machine that is fully watertight, allowing for complete washdown. It features stainless steel and anodized aluminum construction instead of painted surfaces that can chip. The T2 offers QuickClick technology for precise blade adjustments and can be run in tandem configurations of up to four machines. It’s recognized as the #1 used trimming system among commercial producers worldwide1117.

Safety and Support

57. What safety features does the Twister T2 have?

The T2 includes protective covers, safety sensors, emergency stop mechanisms, and belt guards to prevent injuries. The user manual emphasizes important safety procedures, including proper setup, operation, and maintenance guidelines. The T2 is designed to be compliant with health and safety requirements and regulations on a global scale1419.

58. Is the Twister T2 compliant with industry health and safety regulations?

Yes, the T2 was built in conjunction with leading licensed producers to be compliant with health and safety requirements and regulations globally. It’s constructed with stainless steel and food-safe materials, featuring full guarding, safety sensors, and emergency stops to ensure operator safety and product quality14.

59. What warranty comes with the Twister T2?

The Twister T2 comes with a comprehensive 3 year warranty. For more specific warranty information, it’s recommended to contact Twister directly as warranty terms may vary by region and distributor. Twister provides technical support for all their products, and the detailed user manual includes contact information for assistance19.

60. Can the Twister T2 be used for trimming hemp as well as cannabis?

Yes, the T2 is designed for both cannabis and hemp trimming. Its robust construction and powerful motors can handle the typically tougher fiber structure of hemp plants. The machine has been engineered to meet the volume requirements of today’s most demanding cannabis and hemp facilities17.

See the Latest Cannabis News

Built Right, Right From the Jump: Why The T-Zero PRO Is On a Whole Different Level

Intentionally designed. Incredibly effective. T-ZERO PRO delivers.

T-Zero: One Machine, No BS

We’re pushing 125 to 150 lbs/hr on the regular and hitting 200 sometimes

Why We’re Ditching ****** and Rolling Back to Twister

Invested in a setup thinking it would work but it didn’t and switched to Twister

The Ferrari of Trimmers: Twister T-Zero PRO

They pulled the trigger on a T-Zero for their harvest

From Chaos to Control: Why These 2 Producers Bet Big on the Twister T-Zero

Two producers hit the wall during harvest season one overwhelmed, the other burned out…

Automated Grading in Cannabis: Revolutionizing Quality Control with Advanced Vision Systems

Introducing a state-of-the-art automated cannabis grading machine, revolutionizing quality control.

Unveiling the Future: Marvel Gen 2

We are thrilled to announce the arrival of Marvel Gen 2, the latest...

A Marvel-ous Evolution in Cannabis Consistency

In today's fast-paced market, consumers demand consistency. They...

The Ultimate Nerds Guide to Curing Cannabis

We’ve created multiple guides to curing cannabis to share with you.

The Dawn of a New Quality Era in (Grading) Cannabis

As the cannabis industry blossomed, consumers became ever more...

Elevate Your Cannabis Production Quality: Unlocking the Power of Continuous Employee Training

In today’s cut-throat cannabis market, merely achieving exceptional...

The Complete Guide to GMP Certification in the Cannabis Industry

GMP is a popular topic among the cannabis industry and its...

Cannabis Automation

Why Cannabis Automation is Important Cannabis automation has become...

The Hidden Costs of Commercial Cannabis Trimming Machines

Uncovering the Hidden Costs of Commercial Cannabis Trimming...

How does cannabis dust affect air quality?

As the cannabis industry evolves, many regions are now tightening up...

Trimming Machine Throughput Called Out

As the cannabis industry continues to develop, there is a lack of...

Cannabis Flower Brands with Consistency Win

Cannabis flower brands that are consistent have a much better chance...

How Loud is a Cannabis Trimming Machine?

Are Cannabis Trimming Machines Loud? The noise from cannabis...

How Important is Uptime in Cannabis Processing Facilities?

Understanding the Importance of Uptime in Cannabis Facilities Uptime...

How to Choose a Cannabis Trimming Machine

As the cannabis industry continues to grow, so does the need for...

Cannabis Size Sorting

How is Cannabis sorted? Sorting Cannabis has long been a practice...

Protecting Cannabis Brand Reputation

Grammy Award nominated Don Carlos – Protecting a brand As the owner...

Take the Trim Challenge – Hand Trim vs Twister

Think you have what it takes? One of the images below is trimmed by...

Trimming Craft Cannabis with Twister T4

*Transcribed from video above The Twister Grow Facility -We don’t...

Twister T4 Trimmer Spotlight and Giveaway

Choosing the right trimming machine for your cannabis depends on...

What to Consider when Drying and Curing Cannabis

Drying can be one of the most challenging parts of the cannabis...

Behind The Harvest – Ep 01 w/ Justin Cooper of Growing Exposed

In the inaugural episode of Behind The Harvest, Paul is joined by a...

Keirton Named One of Canada’s Top Small and Medium Employers for 2021

It’s with immense pride that we announce that Keirton has been named...

Cannabis Growth Considerations: How to Prevent Post-Harvest Rot

After a lengthy growing season, you’re finally harvesting your crop...

How to Trim Cannabis Plants: Ensuring Cannabinoid Potency and Quality

The quest for high quality cannabinoids doesn’t end when the plant...

Global CBD Statistics 2021

Global CBD Statistics 2021 CBD oil is most popular in the United...

Marijuana Statistics USA 2021

As you’re probably already aware, different states have very...

Product Spotlight: Twister T2

| Choosing the right machine for your cannabis trimming depends...

Cooked With Cannabis’ Review

Photo Courtesy of Netflix Television viewers have always had a bevy...

Marijuana Legalization in Canada and the USA

Cannabis is fully legalized in Canada and in some states in the USA....

Forbes Feature : CEO Jay Evans

Keirton CEO Jay Evans is taking his passion for innovation, trimming...

Differences Between Marijuana and Hemp

Cannabis, marijuana, and hemp are commonly used interchangeably...

Difference between THC and THCA

Tetrahydrocannabinol (THC) and tetrahydrocannabinolic acid (THCA)...

Cannabis Market Trends During COVID-19

The outbreak of the 2020 Coronavirus has undoubtedly taken a toll on...

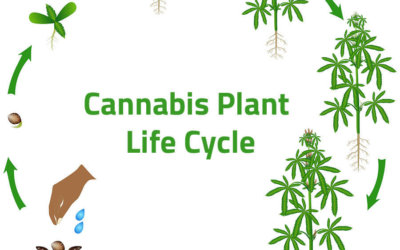

From Seed to Bud: The Plant Life Cycle of Cannabis

The popularity of marijuana plants is rife at different...

Cannabis as a Superfood

Cannabis is rich in natural nutrients that can boost the immune...

Starting your First Grow: When to Trim Your Cannabis

Over the years, cannabis trimming has been a controversial topic...

What to do with Cannabis Trim

Cannabis trim is a term referring to all waste obtained after...

The Best 5 Trimmers for All Your Needs

Trimming marijuana after harvesting is a delicate process that...

How to Maximize Cannabis Yields

Yield is not all about the amount of cannabis harvested,...

Wet Vs Dry Trimming

Bud trimming refers to removing all unwanted plant materials around...

How to Dry Trim

Dry trimming cannabis is a crucial step in determining the quality...

Product Spotlight : Batchone Dry Trimmer

Product Spotlight : Batchone Dry Trimmer Growing cannabis takes a...

How to Get the Most Profit from your Hemp Harvest

If you haven’t already, it’s time to start thinking about harvesting...

The Power of Automation for Harvesting Cannabis: Cultivate Podcast Ep. 10

In May 2018, while attending Lift Expo in Toronto, we sat down to...