Built Right, Right From the Jump: Why the T-Zero PRO Is the Industrial Cannabis Trimmer You’ve Been Waiting For

Thoughtful Engineering, Built for What’s Next

It’s immediately clear when a machine has been thoughtfully engineered, and thoughtful engineering is what we do – The T-Zero PRO is a prime example. Every element of this machine reflects intentional design. It isn’t a showpiece with no substance; it’s a robust, industrial-grade cannabis trimmer built on a platform designed to evolve.

The foundation supports future-ready features like automated flower feeding using Oracle – Twister’s laser triangulation cannabis metering accessory – or real-time cannabis grading for under-trimmed flower, mold and foreign material removal using Marvel – another thoughtfully engineered machine.

“There’s a lot really meaningful and intentional design there, and it looks like a really solid foundation for which they can build ancillary products for.” (Corey Lord, Cultivation Director, Grip)

And this is just the beginning. With this foundational infrastructure in place, it’s only a matter of time before we unlock additional features, upgrades, and system integrations that further raise the bar. Much like how Tesla redefined autonomy, pioneering and owning self-driving, Twister is redefining cannabis trimming with automation. Telsa owns self-driving. Self-Trimming by Twister? Has a nice ring to it…

Performance that Delivers from Day One

Straight out of the box, the T-Zero PRO performs exceptionally well. Nothing else on the market comes close.

“The T-Zero has a super large capacity, on average we’re hitting 125-150lbs/hr, it can go up to 200.” (Logan Hey, Director of Farming, Grip)

Its clean, streamlined design delivers exactly the throughput today’s operations require.

Built with 304 stainless steel, self-sharpening blades, and industrial-grade controls, it’s made to withstand the demands of high-volume production.

“It’s super simple, cleans really well, blades stay sharp they’re self-sharpening.” (Corey Lord)

Air quality is another massive standout with the T-Zero PRO and is often overlooked by uninformed producers. First, the 304 stainless steel cyclone captures kief particles down to 20-micron, preserving them for extractions or pre-roll infusions. Gone are the days when this white gold made its way past a fragile, 75-micron nylon mesh bag, torn to pieces after a few days of use, only to cake your walls.

Next, the 2-Stage HEPA Filter Stack returns hospital-grade air back to your trim room, significantly reducing allergens, ultra-fine airborne particles, and the need for respiratory protection.

“The trim dust was brutal. Respirators were required when we had the [old trimmers] in our trim room, but now they’re optional.” (Tar Deol, Former Director of Infrastructure, 7 Acres/Supreme)

That translates into a safer environment, fewer interruptions, smoother workflows, fewer frustrating maintenance calls, and more cash in your pocket.

Designed for Real-World Cannabis Producers

Another thoughtful intention is the T-Zero PRO’s approach to cleaning and maintenance. The system is fully accessible and can be pressure washed – no more wishing you could clean those hard-to-reach areas or using a toothbrush on sensitive and proprietary electronics.

“It can open up and get pressure washed, so from a sanitation and wear and tear [standpoint] on the machine, being able to do that is a whole different ballgame.” (Charlie McKenzie, Director of Cultivation, Heritage Farms)

This isn’t like trying to scrub down a college dorm with a toothbrush and bucket. It’s a significant leap forward in sanitation – like taking your Super Duty to the Super Turbo Wash World – dramatically reducing wear and tear while making daily operations more efficient.

More Than a Trimmer – It’s a Scalable Platform

The T-Zero PRO isn’t just a high-performance trimmer; it’s a forward-thinking solution, built for the future of post-harvest processing. From its hardware to its digital integrations, it’s designed to grow with your business. It opens new capabilities, improves throughput, and simplifies the trimming process every step of the way.

See the Latest Cannabis News

Twister’s T-Zero: The Cannabis Trimming Machine Backed by Elite Customer Service

When it comes to investing in an advanced cannabis trimming machine,...

T-Zero: One Machine, No BS

We’re pushing 125 to 150 lbs/hr on the regular and hitting 200 sometimes

Why We’re Ditching ****** and Rolling Back to Twister

Invested in a setup thinking it would work but it didn’t and switched to Twister

The Ferrari of Trimmers: Twister T-Zero PRO

They pulled the trigger on a T-Zero for their harvest

From Chaos to Control: Why These 2 Producers Bet Big on the Twister T-Zero

Two producers hit the wall during harvest season one overwhelmed, the other burned out…

Automated Grading in Cannabis: Revolutionizing Quality Control with Advanced Vision Systems

Introducing a state-of-the-art automated cannabis grading machine, revolutionizing quality control.

Unveiling the Future: Marvel Gen 2

We are thrilled to announce the arrival of Marvel Gen 2, the latest...

A Marvel-ous Evolution in Cannabis Consistency

In today's fast-paced market, consumers demand consistency. They...

The Ultimate Nerds Guide to Curing Cannabis

We’ve created multiple guides to curing cannabis to share with you.

The Dawn of a New Quality Era in (Grading) Cannabis

As the cannabis industry blossomed, consumers became ever more...

Elevate Your Cannabis Production Quality: Unlocking the Power of Continuous Employee Training

In today’s cut-throat cannabis market, merely achieving exceptional...

Save Millions of Dollars

A million-dollar question deserves a million-dollar answer:A...

The Complete Guide to GMP Certification in the Cannabis Industry

GMP is a popular topic among the cannabis industry and its...

Cannabis Automation

Why Cannabis Automation is Important Cannabis automation has become...

The Hidden Costs of Commercial Cannabis Trimming Machines

Uncovering the Hidden Costs of Commercial Cannabis Trimming...

How does cannabis dust affect air quality?

As the cannabis industry evolves, many regions are now tightening up...

Trimming Machine Throughput Called Out

As the cannabis industry continues to develop, there is a lack of...

Cannabis Flower Brands with Consistency Win

Cannabis flower brands that are consistent have a much better chance...

How Loud is a Cannabis Trimming Machine?

Are Cannabis Trimming Machines Loud? The noise from cannabis...

How Important is Uptime in Cannabis Processing Facilities?

Understanding the Importance of Uptime in Cannabis Facilities Uptime...

How to Choose a Cannabis Trimming Machine

As the cannabis industry continues to grow, so does the need for...

Cannabis Size Sorting

How is Cannabis sorted? Sorting Cannabis has long been a practice...

Protecting Cannabis Brand Reputation

Grammy Award nominated Don Carlos – Protecting a brand As the owner...

Take the Trim Challenge – Hand Trim vs Twister

Think you have what it takes? One of the images below is trimmed by...

Trimming Craft Cannabis with Twister T4

*Transcribed from video above The Twister Grow Facility -We don’t...

Twister T4 Trimmer Spotlight and Giveaway

Choosing the right trimming machine for your cannabis depends on...

What to Consider when Drying and Curing Cannabis

Drying can be one of the most challenging parts of the cannabis...

Behind The Harvest – Ep 01 w/ Justin Cooper of Growing Exposed

In the inaugural episode of Behind The Harvest, Paul is joined by a...

Keirton Named One of Canada’s Top Small and Medium Employers for 2021

It’s with immense pride that we announce that Keirton has been named...

Cannabis Growth Considerations: How to Prevent Post-Harvest Rot

After a lengthy growing season, you’re finally harvesting your crop...

How to Trim Cannabis Plants: Ensuring Cannabinoid Potency and Quality

The quest for high quality cannabinoids doesn’t end when the plant...

Global CBD Statistics 2021

Global CBD Statistics 2021 CBD oil is most popular in the United...

Marijuana Statistics USA 2021

As you’re probably already aware, different states have very...

Product Spotlight: Twister T2

| Choosing the right machine for your cannabis trimming depends...

Cooked With Cannabis’ Review

Photo Courtesy of Netflix Television viewers have always had a bevy...

Marijuana Legalization in Canada and the USA

Cannabis is fully legalized in Canada and in some states in the USA....

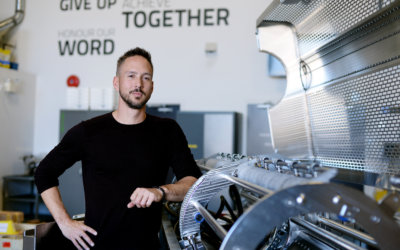

Forbes Feature : CEO Jay Evans

Keirton CEO Jay Evans is taking his passion for innovation, trimming...

Differences Between Marijuana and Hemp

Cannabis, marijuana, and hemp are commonly used interchangeably...

Difference between THC and THCA

Tetrahydrocannabinol (THC) and tetrahydrocannabinolic acid (THCA)...

Cannabis Market Trends During COVID-19

The outbreak of the 2020 Coronavirus has undoubtedly taken a toll on...

From Seed to Bud: The Plant Life Cycle of Cannabis

The popularity of marijuana plants is rife at different...

Cannabis as a Superfood

Cannabis is rich in natural nutrients that can boost the immune...

Starting your First Grow: When to Trim Your Cannabis

Over the years, cannabis trimming has been a controversial topic...

What to do with Cannabis Trim

Cannabis trim is a term referring to all waste obtained after...

The Best 5 Trimmers for All Your Needs

Trimming marijuana after harvesting is a delicate process that...

How to Maximize Cannabis Yields

Yield is not all about the amount of cannabis harvested,...

Wet Vs Dry Trimming

Bud trimming refers to removing all unwanted plant materials around...

How to Dry Trim

Dry trimming cannabis is a crucial step in determining the quality...

Product Spotlight : Batchone Dry Trimmer

Product Spotlight : Batchone Dry Trimmer Growing cannabis takes a...

How to Get the Most Profit from your Hemp Harvest

If you haven’t already, it’s time to start thinking about harvesting...